A carvel-planked boat has many hundreds of fastening holes to plug as well as a few repairs to plank surfaces where knots are exposed. Here’s how I went about it.

Author Archives: Ian Smith

Knees are used to brace the hull and deck in the main load areas like the beams adjacent to the mast, cockpit and cabin structures and in the bow and stern. Ian Smith shows how he fitted knees into the 24′ Ranger-class gaff sloop from natural crooks of tea tree and from laminated knees, from cutting out to fastening off.

The deck beams, cockpit structure and the carlins for hatches are all going in to the 24′ Ranger class new build. Ian Smith shows how to lay out the shapes of the deck beams, how to laminate them and how to fit them to the sheer clamp, as well as fitting the hatch carlins, the fore and aft members between deck beams.

The Huon Pine snub dinghy gets its stringers, risers, thwarts, knees and rowlock blocks, and launches it for a trial run. This is the final episode in the series where the Sydney Wooden Boat School Summer School Class of 1999 built two dinghies, a snub and a stem dinghy.

The Summer School class of 1999 turns over the Huon Pine snub dinghy and steam-bends the ribs into the boat, and fastens them off.

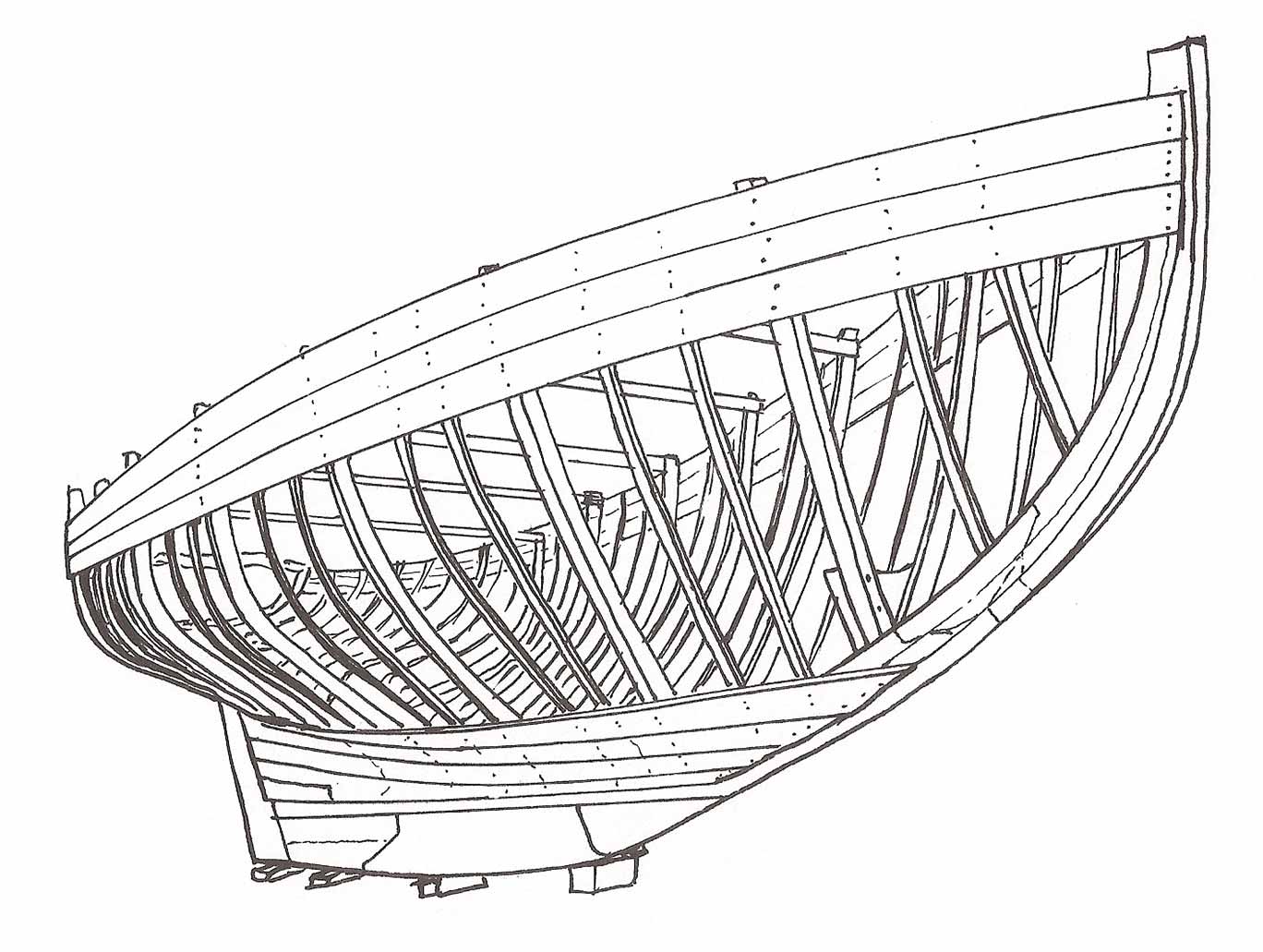

Stringers and clamps are essential longitudinal members of the hull. Here’s how I went about it in the 24′ Ranger.

The 24′ Ranger is nearly planked up, only a couple of planks to the lower sheer strake level. I filmed the process of fitting a couple of planks and have put it together as Episode 8 of the Carvel Planking series.

Now we’re getting down to the nitty-gritty of traditional clinker planking, the actual planking itself! The class starts planking the two dinghies, a snub (pram) dinghy and a stem dinghy. In the first few classes I ran back in the early 1990’s, the thing that held most people up was how to make the jerralds (gains or rebates) where the planks are let into each other at the bow and stern. After quite a few ruined planks, I developed a sequence to follow which enables first-timers to get it right every time. It’s not the way it was generally done, but it works! The video follows the class right through the process from deciding how many planks to use, lining out, spiling and marking out, browing off (bevelling), cutting and matching jerralds, drilling for fastenings and fastening off. At the end there is a two-minute summary.

In this episode I show how to fit engine beds and mast steps from big chunks of hardwood.

For over 150 years Sydney’s open boat sailors have called the spar out the front of the boat a bumpkin, whereas yachties would call it a bowsprit. This video shows the reasons why this is the case. It also shows stages in the shaping of a new bumpkin for the 18-footer replica Yendys from a select piece of clear Oregon Pine (Douglas Fir).

The Summer School class of January 2000 is building two dinghies. In this episode we set up both boats, the pram dinghy upside down and the stem dinghy right way up.

Here’s the third episode as promised. The class marks out and cuts out the moulds, knees and transoms to build two small clinker dinghies.

We filmed a Summer School class in 2000, and it’s taken me until now to edit it. It’s the first in a series which will eventually be accompanied by a thorough book on Traditional Clinker Construction. The first two episodes are here, the following episodes will appear….well, episodically, probably a few months apart. I’ve explained some complicated processes as best I

can, but you’ll still need a textbook. If you want to start your project before the series finishes and the book comes out, you can get a fair bit on lofting from both THE OPEN BOAT and WOODEN BOATBUILDING- THE SYDNEY WOODEN BOAT SCHOOL MANUALS, and the latter also includes the original manual on Building a Traditional Clinker Dinghy.

Splining cracks in clinker planks.

BRITANNIA gets a new ringtail spar by the traditional method.

After 16 hard seasons of racing a few planks on the batten-seam carvel hull needed repairs.

Fitting structural floor timbers to my carvel-planked Ranger class gaff sloop.

How I drilled for the shaft tube on my 24′ traditional gaff sloop.

Stealer planks are let into a host plank where the host plank can’t be wide enough to cover the area it needs to.

Stopwaters prevent water migrating along joints in the backbone timbers in carvel-planked construction.